Rebuilding a Bowl Chopper

For almost 30 years M&M Equipment has been rebuilding commercial bowl choppers in our Chicagoland facility. We have extensive background in rebuilding Seydelmann, Laska, Talsa, Nowicki, and many other well known industry brands. When we rebuild a bowl chopper from the frame, we take into account everything that the customer will need for their desired product.

The first step is always a three part assessment of any used machine which consists of recording all requirements on mechanical, cosmetic, and electrical work. Our process usually begins with an older machine, in some cases it can even be a machine from the 1970s or 1980s that we strip down to the frame. The team removes all interior components so that we can focus on reconditioning the frame for new assembly. In addition, our team starts by cleaning and sterilizing the frame so that it is ready to receive all new or reconditioned parts.

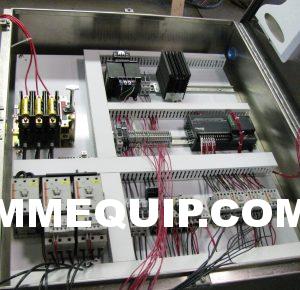

The interior of the frame is painted with hammer hard non-chip paint and the motor is rebuilt with new bearings, seals, and a new paint job. The knife shaft bearings and seals are also replaced along with the drive belts from the motor to the knife shaft. The gear box that usually sits under the bowl is replaced with new oil. Our electrical team gets to work building all new controls usually with NEMA 4X controls which are placed into a water tight cabinet. We typically use variable frequency drive with two speed bowl and knife with a slow mix speed as well.

From a cosmetic side, all of the panels and exteriors of the machine will be polished to make the machine shine. The bowl is also polished and we install new or sharpened knifes. The motor on the unloading arm is removed and we replace the bearings, seals, and gaskets. If required, we can implement new motors after our project management team makes an initial assessment of the as-is condition.

We implement all new start / stop buttons separate from the main panel. We build new electrical enclosures with new wires and connect it to the chopper in whichever manner the customer would like for their facility.

Lastly, our team rigorously tests and goes through safety protocols checking that everything is working properly. We ensure that safety switches are installed in addition to variable frequency drives so that when the lid is opened, reverse power will be enacted forcing the knife shaft to stop immediately.

After testing, our logistics team gets to work taking videos and photos for our customers and building a custom skid for the machine and electrical enclosures for a safe journey on one of our trusted freight carriers.

For more information about industrial or commercial bowl cutters for food processing please reach out to one of our sales representatives by emailing [email protected] or calling our office at 847-673-0300.