The Intriguing Journey of Sausage and Hot Dog Production: A Large-Scale Affair

Welcome to the world of large-scale sausage and hot dog production! At M&M Equipment, we understand the intricacies of industrial food processing machinery, and today, we’re going to take you through the fascinating process of how sausages and hot dogs are made commercially.

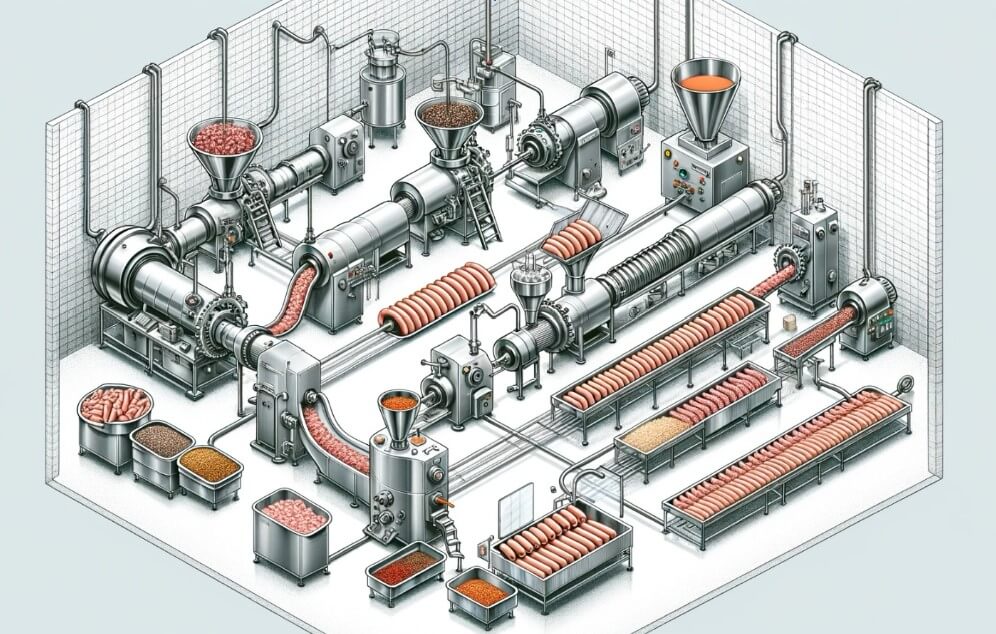

Step 1: Grinding the Meat

It all begins with the grinding phase. Quality meat cuts are selected, typically beef, pork, or a combination, and then ground. The grinding is done multiple times to achieve the desired texture. Different grinders with varying blade sizes are used to ensure that the meat is finely ground, which is essential for the smooth texture of hot dogs and the slightly coarser consistency of sausages.

Step 2: Mixing

Once the meat is ground, it’s time for mixing. This is where flavors are crafted. A concoction of spices, ice chips or water, and curing agents are added to the meat. The mixture is then blended until the ingredients are evenly distributed. It’s crucial that the meat stays cold during this process to prevent fat from melting, which could affect the texture and taste.

Step 3: Filling with a Vacuum Stuffer

The mixed meat is then transferred to a vacuum stuffer, such as a Vemag or Handtmann. These machines are the workhorses of sausage and hot dog production. They play a critical role in ensuring that the filling is consistent and free of air pockets, which is vital for maintaining quality and ensuring the longevity of the product.

Step 4: Twisting into Links

For sausages, the stuffer also portions and twists the meat into links, creating individual sausages. Hot dogs, on the other hand, may be linked later in the process.

Step 5: Cooking in a Smokehouse Oven

The sausages are then hung or placed on racks and cooked in a smokehouse oven. This step is where the magic happens, infusing the sausages with a rich, smoky flavor while cooking them to perfection. Hot dogs also go through this cooking process, which often includes smoking for flavor and steam cooking to the right internal temperature.

Step 6: Cooling and Peeling

After cooking, the products are cooled to stop the cooking process. Hot dogs are then typically sent through a peeler, where the casings are removed, giving them their smooth, uniform appearance.

Step 7: Packaging

The final step in the production line is packaging. A thermoform rollstock packaging machine, such as a Multivac, is used to package the sausages and hot dogs. These machines vacuum-seal the products into plastic packaging, ensuring they are airtight and ready for distribution. This packaging not only preserves the product’s flavor and freshness but also makes it ready for the retail shelves.

At M&M Equipment, we pride ourselves on providing high-quality, used industrial food processing machinery that makes this entire process efficient and cost-effective. Our expertise in selecting and refurbishing equipment like grinders, vacuum stuffers, smokehouse ovens, and packaging machines ensures that your food processing needs are met with the highest standards.

Whether you’re in the market to buy or sell used food processing equipment, we’re here to ensure that the machinery at the heart of your operations is the best in the business. Join us as we continue to support the journey of food from farm to table, one delicious sausage or hot dog at a time.