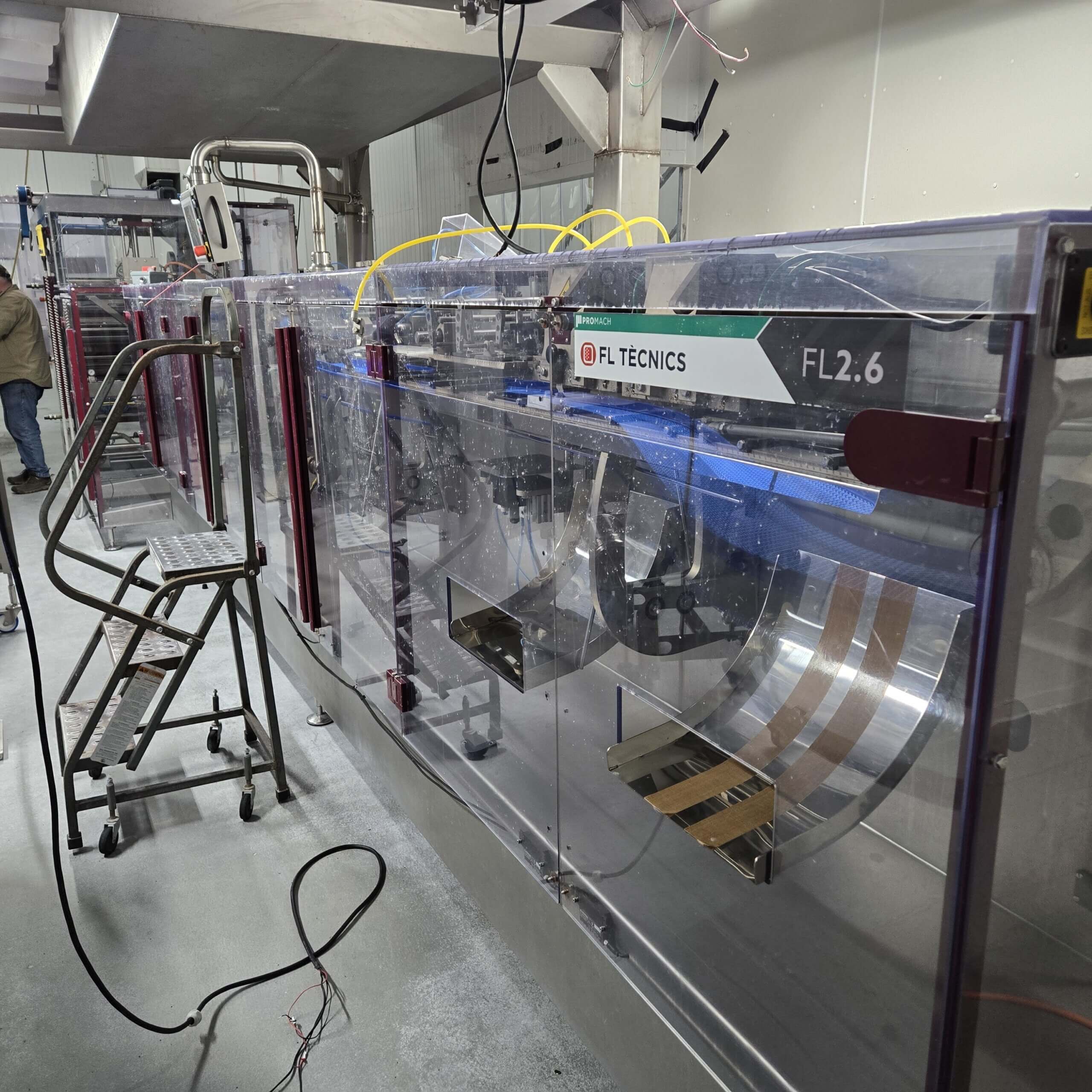

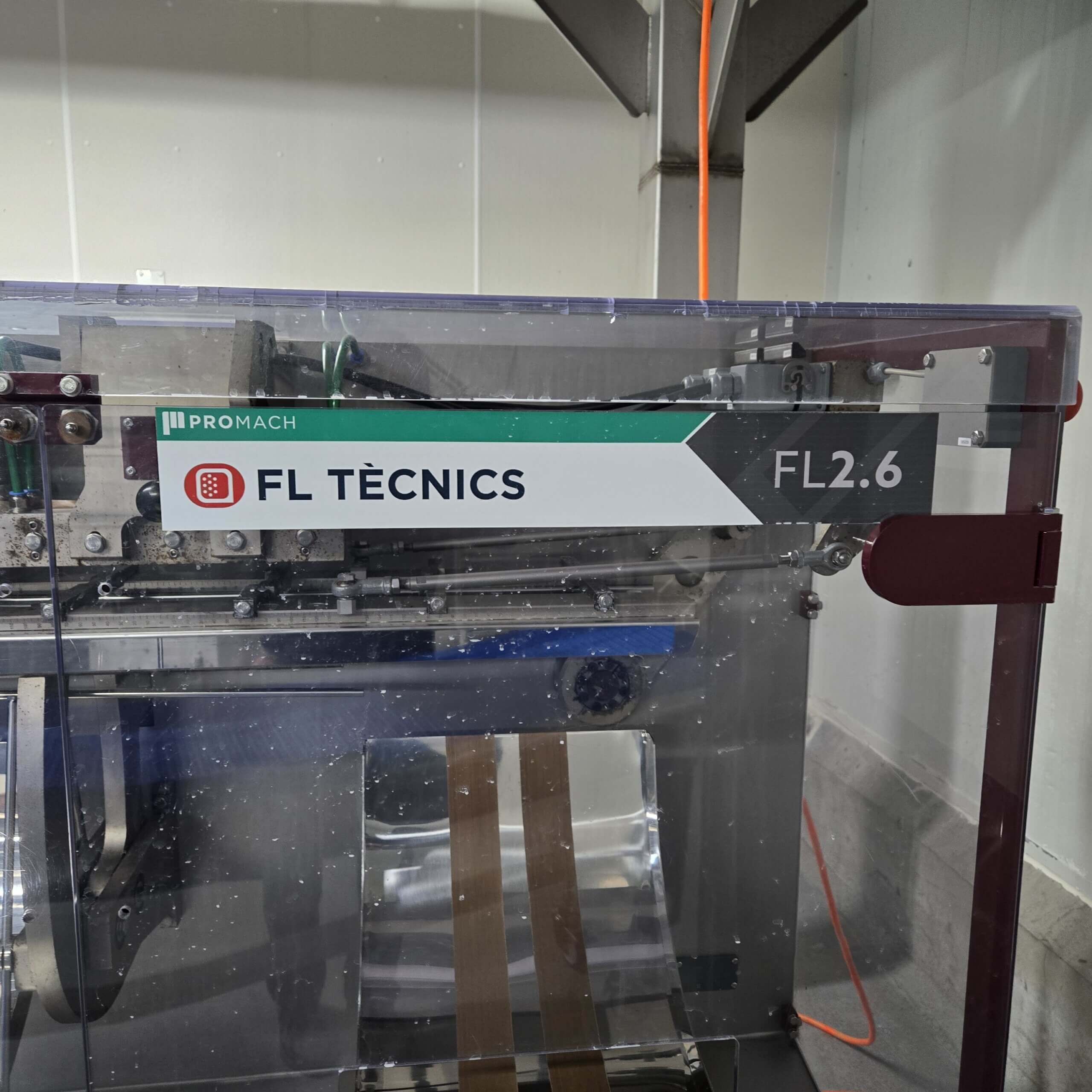

FL Tecnics FL 26 MC STU1 HFFS Bagging System

FL Tecnics FL 26 MC STU1 HFFS Bagging System

This Listing is

Closed / Sold Now

Browse Our Other "Rollstock Packaging Machines" "Vacuum Packaging Equipment"

OR

Browse more from Same Manufacturer: FL Tecnics

OR

You can also Call us at : +18476730300 OR Email us at: [email protected]