Heat is required in industrial food plants and processes to eliminate risk and transform food into a digestible and appetizing element. On industrial food plants, everything from sanitation to pasteurization, packaging, and making potential food depends on the heat transferred from boilers. Food boilers are heat-exchanging equipment that offers better efficiency, less reliance on fossil fuels, and reduced energy costs for transferring heat to different phases of food preparation.

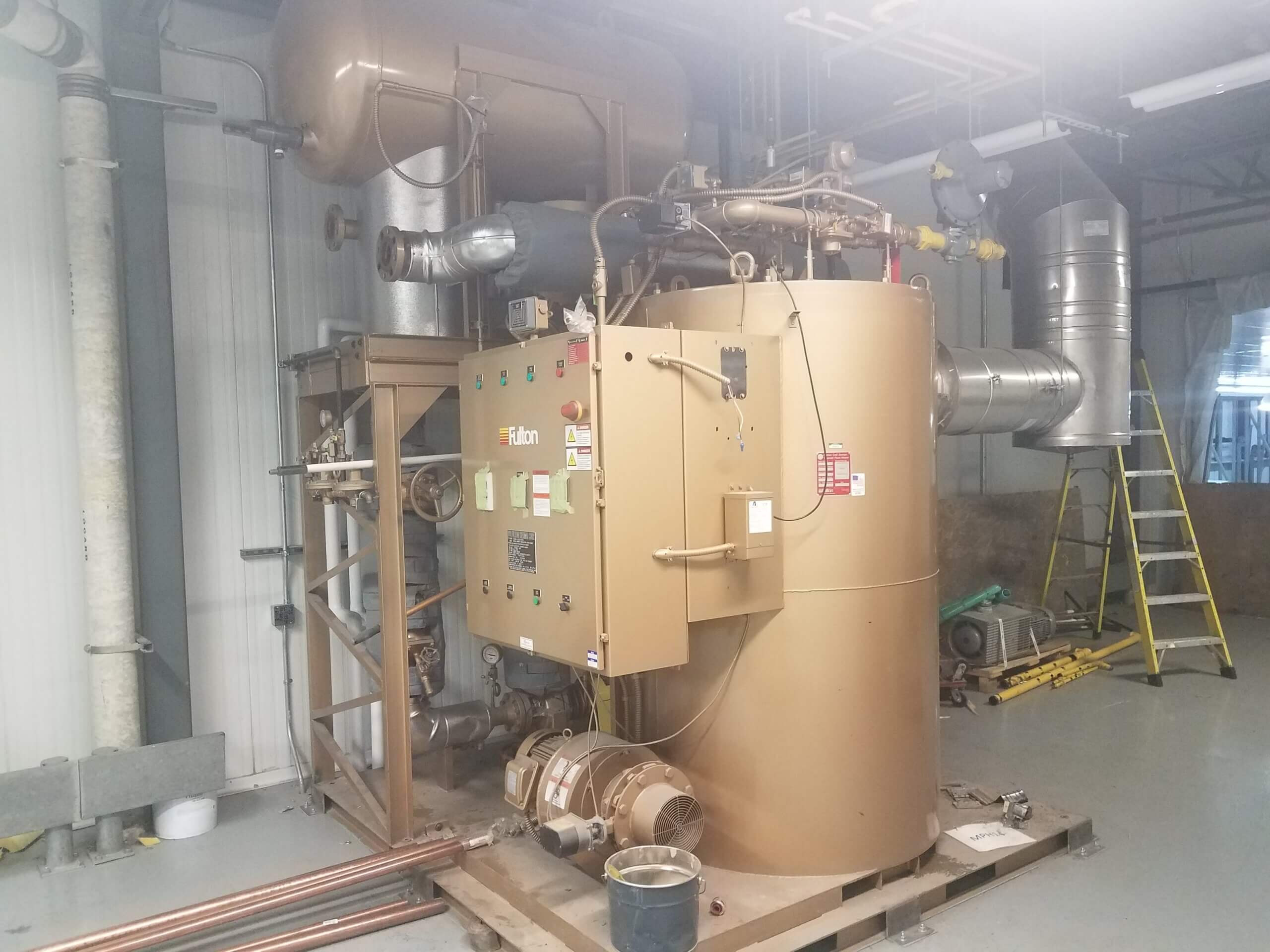

Globally, there is a variety of food boilers in the manufacturing market that continue to expand their applications and emulsify productivity with business. Industrial boilers can withstand higher pressures and use various facilities for various applications. Commercial food boilers are built on low-pressure streaming models that can provide a high level of productivity and operational durability in a short amount of time. Many manufacturers design food boilers depending on the variety of food operations. However, M&M food boilers are not only versatile in design and functions but their utilization and application in different food kitchens and manufacturing plants are also noticeable. From vertical tubeless boilers to micro burners, M&M equips different types of food boilers in their inventory and caters to global operations effectively.