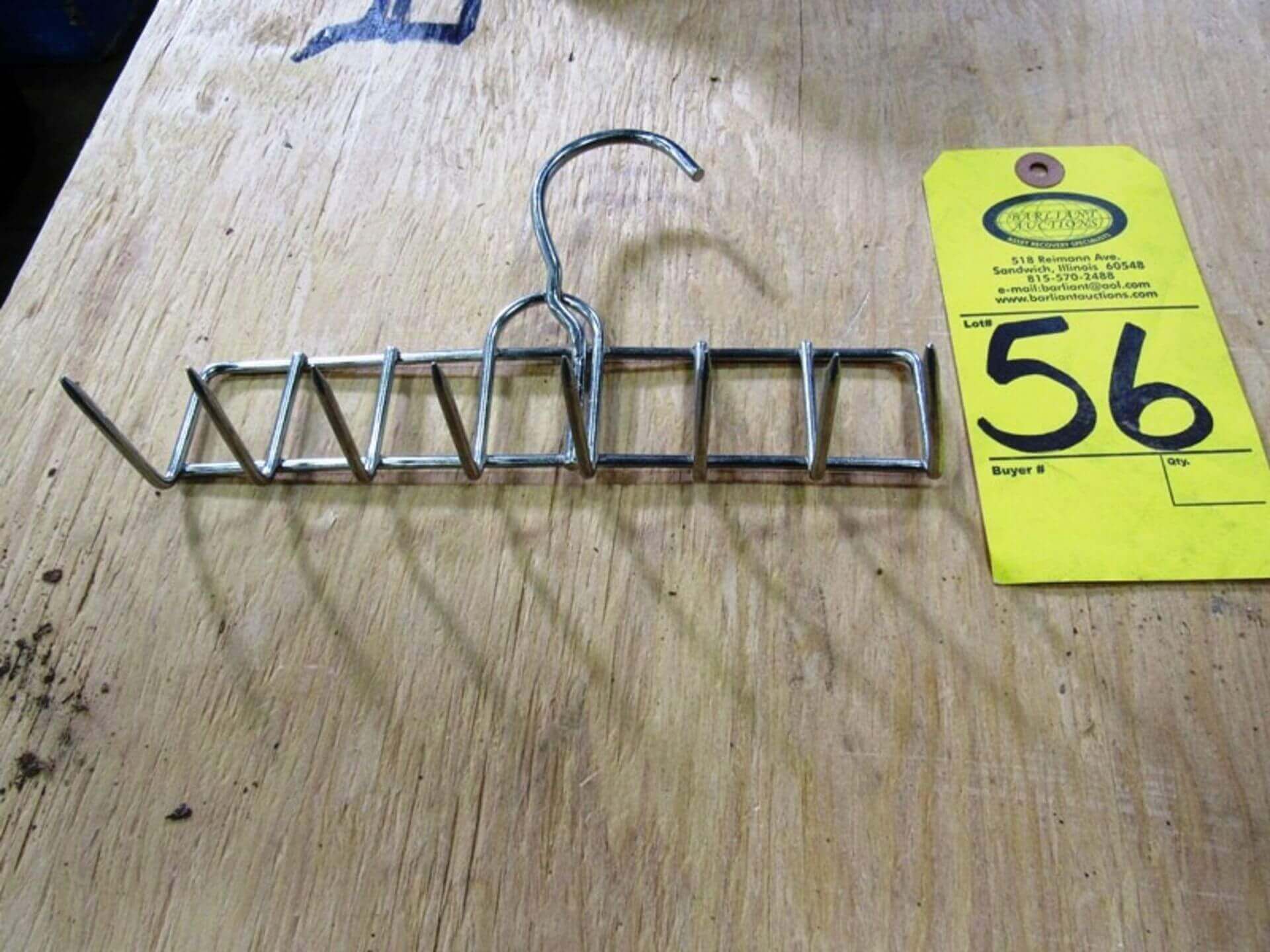

Bacon Combs

Our bacon combs are designed to meet the requirements of your bacon-processing operations. They feature heavy-duty components and construction, to ensure durability and to be able to handle the toughest tasks in the harshest working environments. Our bacon combs are user-friendly, and meet all the sanitary requirements; they are easy to clean and maintain.

-

Item#: 10009

M&M Equipment Corp. Bacon Combs

M&M Equipment Corp. Bacon Combs. (870) 10 Prong Bacon Combs, stainless steel con...

View More > Add To Quote -

Item#: 3383

Smoke Sticks, Bell Shape

Smoke Sticks, 18 gauge stainless steel, bell-shaped, available in 42″ and 39.2...

View More > Add To Quote

In commercial food manufacturing plants, the significance of Bacon holds no constraints. Bacon is not only a staple food item in the food industry but its consumption crosses higher than meat dishes at any time in food history. Bacon in the food industry goes beyond a condiment or crisp flavorful consumption to become a major component of breakfast and meat dishes. Therefore no commercial food manufacturing plant denies its usage in the food industry.

Bacon comes from pork bellies and pork bellies must be hung vertically on bacon combs for proper texture and shape. Bacon combs function in a triangular wire framework with a central upper hook. It allows the meat to lean and automatically unify the pork muscles. Bacon combs become essential in commercial food manufacturing plants as proper hanging before smoking gives them a characteristic taste and crispiness. The effective and efficient way for producing bacon slaps in regular shapes and slicing in a commercial setting is only durable through the automated lean process of bacon. Thus, its significance in commercial kitchens becomes crucial.

Bacon combs are growing in the food industry making the process easier and cost-effective. Through bacon combs the slicing of pork belly becomes uniform and no safety hazard or gems are penetrated during the thermal heating process. The usage of bacon combs and smoke sticks allows the process to be cleaner and safer for the food facilities with little attention to the manufacturing process. The effectiveness and functionality of bacon combs in the commercial setting go beyond its traditional usages and food experts now recommend the adoption of bacon combs in kitchen operations for trimming to slicing and further packaging as best solutions to decrease the overall cost and involve best practices for processing equipment in kitchen plants.